Introduction

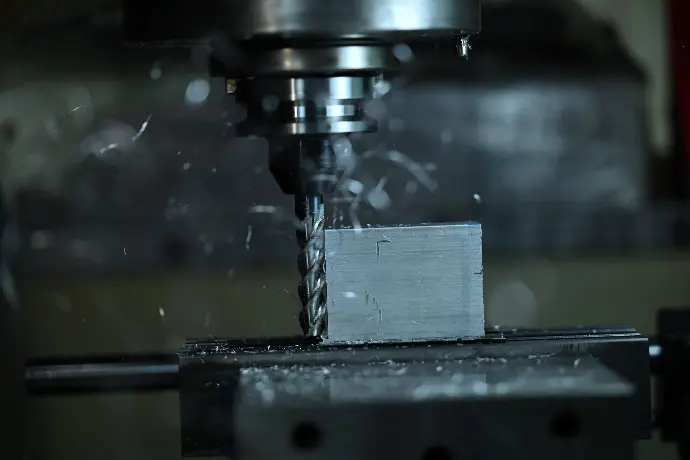

CNC machining, short for computer numerical control machining, is a manufacturing process that employs computer-aided machines to cut metals and other materials into precise patterns and shapes. It offers numerous advantages that position it as a pivotal technology across various industries.

Throughout this blog, we will explore some of the key advantages that CNC machining offers in different applications.

1. CNC Machining Generates Minimal to No Waste

CNC machining excels in minimizing material waste with its precision and accuracy. By designing parts meticulously in the computer, the machine executes cuts with minimal error, reducing defective pieces and handling intricate cuts and angles effectively, thus significantly lowering waste generation.

2. CNC Machining Is More Accurate and Has Fewer Defects

CNC machining's precision is a key benefit. By executing exact instructions from a computer and operating under computer control, CNC machines consistently produce accurate parts that closely match the computer model. This capability minimizes human error, ensuring uniformity in parts production, especially for components with tight tolerances.

3. CNC Machining Offers More Rapid and Effective Production

CNC machining is significantly faster and more efficient than traditional methods, with machines capable of rapid production and autonomous material handling. This automation reduces production time, cuts costs, and enhances overall productivity while ensuring consistent quality across parts.

Get Your Free Quote Today

Don't wait any longer on your project!

4. CNC Machining Makes Assembly Faster

CNC machining ensures precise and consistent parts that fit together seamlessly as designed in the computer model, reducing assembly times and costs compared to manual methods.

5. CNC machining improves safety by automating and reducing risks from manual operations.

CNC machining significantly reduces safety risks on the shop floor by automating the machining process. This automation eliminates many hazards typically associated with manual machining. Furthermore, CNC machines are often enclosed, further mitigating the risk of injury.

6. CNC Machining Uses Little Energy

CNC machining consumes significantly less electricity than traditional methods, about one-seventh according to the EPA, due to its swift operation and lower power usage per minute compared to other manufacturing techniques.

7. CNC Machining Reduces Production Costs

CNC machining offers a cost-effective, efficient, and precise approach to manufacturing parts and products. It reduces raw material usage compared to conventional methods and can substantially lower errors, production costs, and overall expenses when integrated into your shop's operations.

Summary

This article explored the key benefits of CNC machining, offering detailed explanations of each advantage alongside relevant examples. For further insights into the benefits of CNC machining, please reach out to a representative from Accurate Machine Products.

Accurate Machine Products provides a wide range of manufacturing capabilities, including

CNC machining and other value-added services for all of your prototyping

and production needs. Visit our website to learn more or to request a free,

no-obligation quote