When it comes to machining blind holes, two common approaches are drilling and creating flat bottom holes using specialized tools. Though they might appear similar at first glance, drilled blind holes and flat bottom blind holes have distinct differences in design, function, and manufacturing method. Understanding these differences is key to ensuring part performance, dimensional accuracy, and manufacturing efficiency.

In this article, we will explore the definitions of both hole types, compare their uses and manufacturing considerations, and offer practical guidance for engineers and machinists tasked with specifying or producing them.

What Is a Blind Hole?

A blind hole is any hole that does not go all the way through a workpiece. Unlike a through hole, which is open on both ends, a blind hole stops at a predetermined depth. Blind holes are common in parts where a fastener, dowel, or threaded insert needs to be secured without penetrating the entire component.

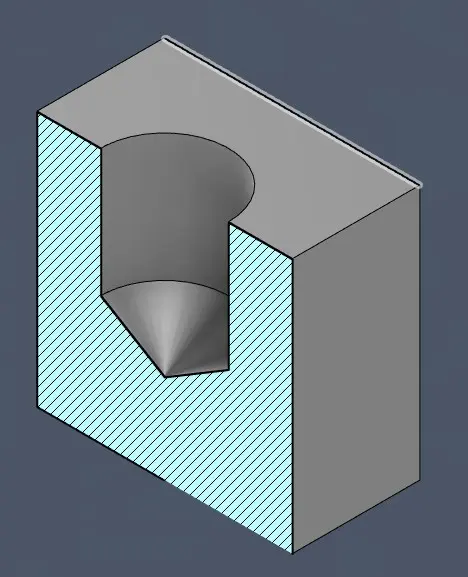

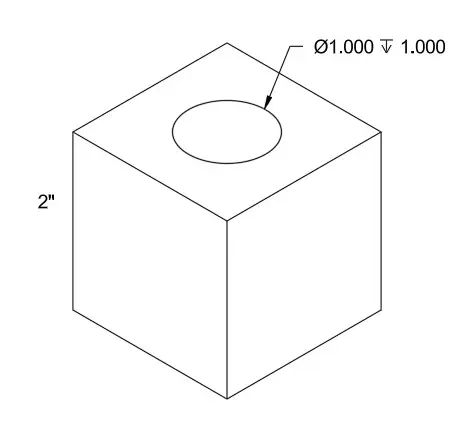

What Is a Drilled Blind Hole?

A drilled blind hole is created using a standard twist drill or center-cutting end mill. The bottom of the hole is conical due to the shape of the drill tip, which typically has a point angle between 118 and 135 degrees. This results in a V-shaped cavity at the bottom of the hole.

|

|

Advantages of Drilled Blind Holes

- Faster to machine: Drilling is typically faster than milling

- Standard tooling: Uses common drill bits available in most shops

- Cost-effective: Requires less machine time and setup

Limitations of Drilled Blind Holes

- Reduced usable depth: The cone at the bottom limits thread engagement or insert depth

- Chip evacuation: Chips can build up and cause surface damage or dimensional issues

- May require follow-up operations: Flat surfaces or precise depths often require secondary machining

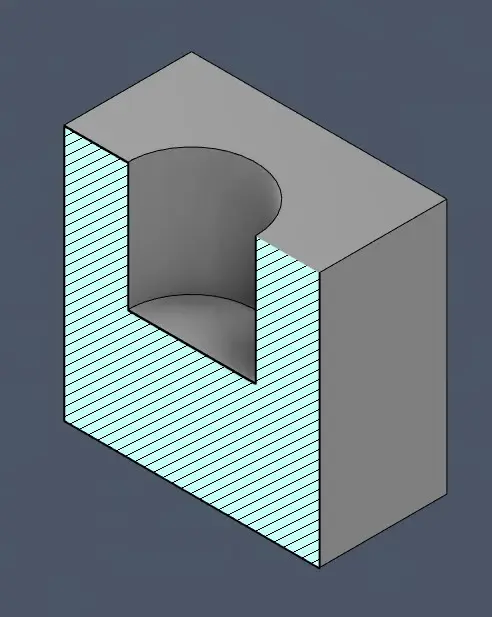

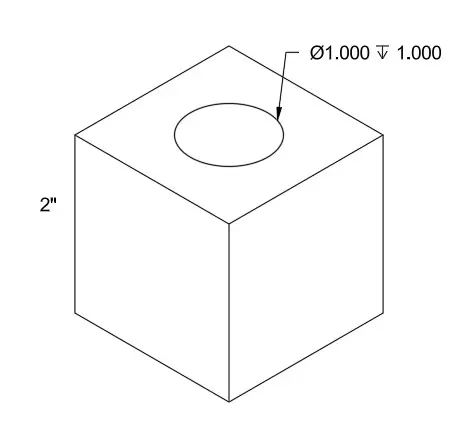

What Is a Flat Bottom Blind Hole?

A flat bottom blind hole has a bottom surface that is perpendicular to the hole axis. It is typically created using an end mill, counterbore, or flat-bottom drill. These holes are essential in applications requiring full thread depth, flat mating surfaces, or uniform contact.

|

|

Advantages of Flat Bottom Blind Holes

- Maximum thread engagement: Threads can extend to the full depth of the hole

- Better load distribution: Flat bottoms allow for even surface contact with fasteners or dowels

- Precision fit: Ideal for components that need consistent seating or tolerance stacking

Limitations of Flat Bottom Blind Holes

- Longer cycle time: Often requires more precise machining with slower feed rates

- Special tooling required: Flat-bottom tools or end mills must be used, especially in harder materials

- Higher cost: Additional machining steps increase time and tool wear

Get Your Free Quote Today

Don't wait any longer on your project!

Design Considerations

Choosing between a drilled and flat bottom blind hole depends on functional requirements, tolerance needs, and production constraints. Key considerations include:

- Threaded holes: For full thread depth, flat bottom holes are preferred. Drilled holes may require spot-facing or bottom-tapping tools to achieve similar results.

- Tolerances: Flat bottom holes provide more consistent depths and bottom surface finishes, which can be critical for fit or sealing.

- Material: Harder materials may require specialty tooling for flat bottom holes, which can add cost and complexity.

- Hole diameter and depth ratio: Deep narrow holes present challenges for both chip evacuation and tool rigidity.

Tooling Differences

For Drilled Blind Holes:

- Standard twist drills

- Spot drills for accuracy

- Pecks or coolant-through tools for deep holes

For Flat Bottom Blind Holes:

- Center-cutting end mills

- Flat-bottom drills

- Counterbores or interpolated milling paths

Using the right tool type ensures both accuracy and surface quality while minimizing tool wear and vibration.

Machining Strategies

Drilled Hole Machining

- Spot drill or center to guide the twist drill

- Use peck drilling for deeper holes

- Monitor chip evacuation and coolant flow

- Optional: Ream or chamfer if higher tolerance or surface finish is needed

Flat Bottom Hole Machining

- Pre-drill or plunge cut with a flat-bottom tool

- Use shallow depth increments to avoid tool deflection

- Mill or interpolate if surface flatness is critical

- Deburr edges to ensure part cleanliness

Conclusion

While both drilled and flat bottom blind holes serve the same fundamental purpose, their manufacturing techniques and performance characteristics vary significantly. Engineers and machinists must evaluate part function, cost, and process capabilities before choosing between the two.

Flat bottom blind holes offer precision and full thread engagement, while drilled holes provide speed and cost-efficiency. By understanding the trade-offs, teams can design and machine parts that meet both performance and production goals.