Introduction

In machining, what constitutes a hole? What are its main categories? What does a hole callout indicate in machining? How do various types of holes differ in their definitions? This blog delves into these questions.

Here are another five kinds of holes commonly encountered in engineering: interrupted, simple, spot face, tapered, and tapered holes.

If you haven't already check out the first part to this blog post for more common types of holes.

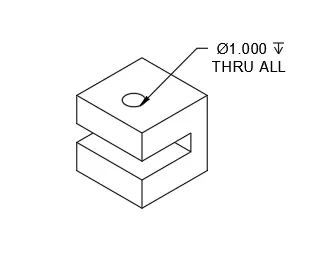

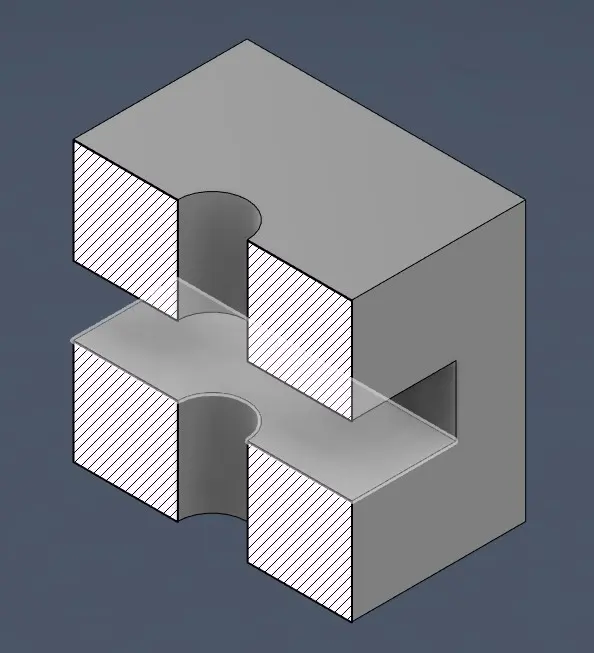

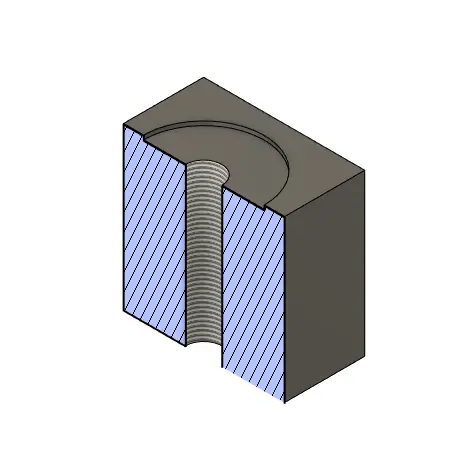

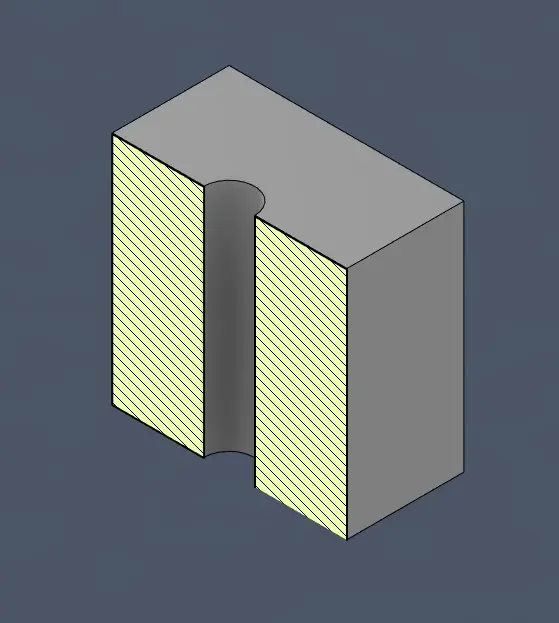

What is an Interrupted Hole?

An interrupted hole, as its name implies, is a hole that intersects with another feature within the material. This type of hole is created by drilling a series of coaxial holes in the workpiece, with gaps in between where the material is not drilled through. Each drilling operation involves both cutting and non-cutting movements to achieve the desired interrupted pattern in the material.

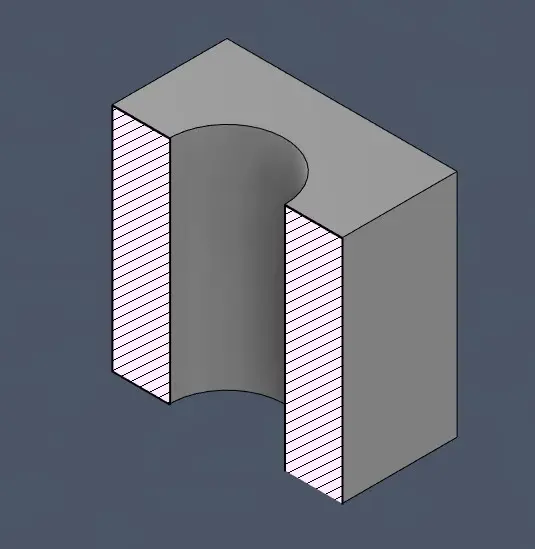

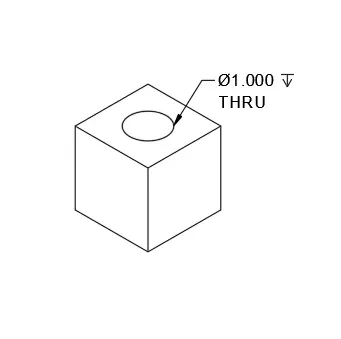

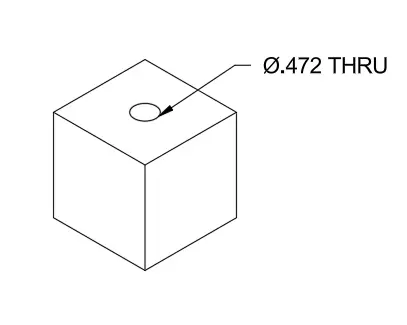

What is a Simple Hole?

In machining, a simple hole refers to a circular cutout made in an object. There are various types of these holes.

What symbol is used to call out a simple hole?

The symbol used to denote a simple hole is 'Ø'. On engineering drawings, simple holes are identified by specifying both the diameter and the exact depth of the hole.

How are simple holes utilized in machining?

Simple holes serve a wide range of purposes in engineering. They are used for creating points where fasteners can be attached, as well as for shaping and assembling various parts and components.

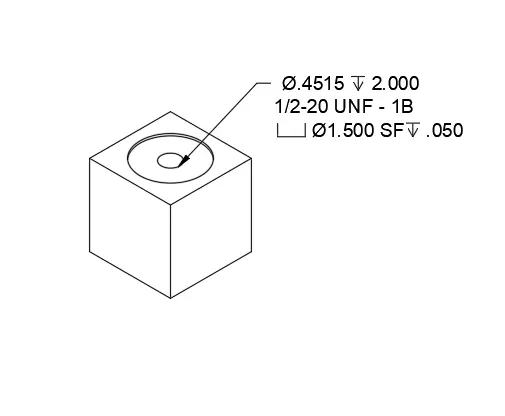

What is a Spot Face Hole?

A spot face hole in machining resembles a counterbore hole but is shallower, designed to provide a flat surface for a fastener to rest on.

What symbol is used to call out a spot face hole?

The callout symbol for a spot face hole incorporates the counterbore symbol 'Ø' with the letters 'SF' inside it.

How are spot faces utilized in engineering?

Spot faces are employed in engineering to create smooth and flat surfaces on machined parts. Components produced through casting may not initially have smooth and flat surfaces like those achieved through machining. Spot face holes ensure proper alignment and seating of parts with rough exteriors when fastened to other components.

Get Your Free Quote Today

Don't wait any longer on your project!

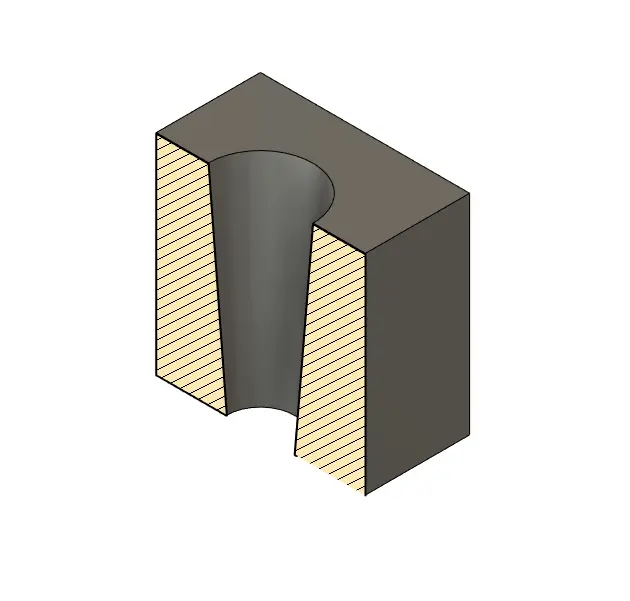

What is a Tapered Hole?

In machining, a tapered hole describes a hole that changes diameter from one end to the other, resulting in a gradual widening or narrowing along its length.

How are tapered holes applied in machining?

Tapered holes serve various purposes in engineering. One frequent application is in securing cutting tools or tool holders, leveraging the taper to ensure precise alignment and secure fitting.

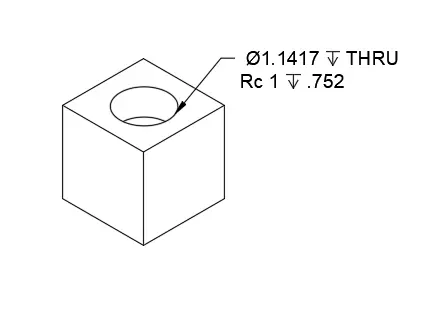

What is a Screw Clearance Hole?

A screw clearance hole in manufacturing refers to a simple hole with a diameter slightly larger than that of a screw thread, allowing the screw to pass through. This type of hole accommodates the threads of a screw or bolt while preventing the head from passing through.

What symbol is used to call out screw clearance holes?

The callout symbol for a screw clearance hole is the same as for a simple hole, accompanied by specifications for its depth.

How are screw clearance holes utilized in machining?

Screw clearance holes are essential in engineering applications where components require screws or bolts to pass through them securely.

How do you determine the size of a screw clearance hole?

The size of a screw clearance hole is calculated by adding the diameter of the screw and the diameter of the screw head, and then dividing the sum by two. This method ensures that the hole is large enough for the screw threads while allowing the screw head to sit flush or slightly recessed. CNC milling machines are often used to create precise screw clearance holes.

Summary

This blog provided an overview of several types of holes used in manufacturing designs, their symbolic callouts, and the specific conditions that determine their usage. Once again if you haven't checked out Part 1 of this blog, we explore additional hole types in machining!

Accurate Machine Products provides a wide range of manufacturing capabilities and value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.