Introduction

In engineering and manufacturing, distinguishing between tapped holes and threaded holes is crucial for precision and functionality across applications. This blog explores the practical uses of tapped and threaded holes in engineering, emphasizing their roles in diverse industries and the importance of understanding their distinctions and callout symbols for efficient manufacturing processes.

What is a Tapped Hole?

A tapped hole in engineering is a hole drilled to accommodate a machine screw, with threads cut into its inner surface through the tapping process.

What symbol is used to denote a tapped hole?

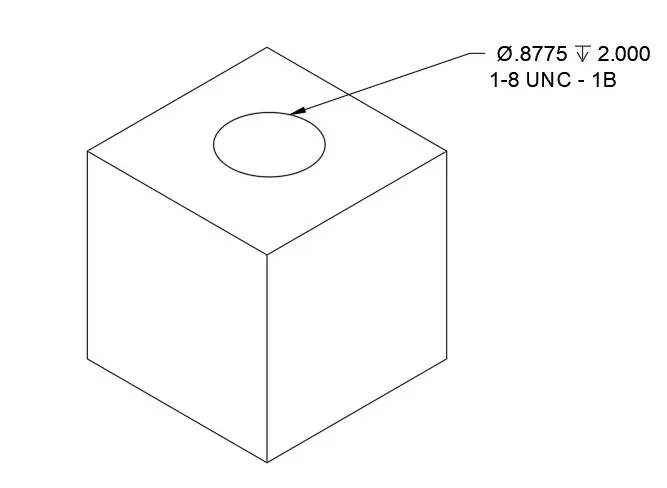

The callout symbol for a tapped hole varies depending on the thread standard used. For metric holes, the diameter symbol is replaced with an 'M'. Different thread types, such as Unified National Fine (UNF), are specified with the numerical dimension followed by "UNF".

How are tapped holes utilized in engineering?

Tapped holes are employed in engineering applications involving metals where nuts and bolts are impractical. They securely hold threaded components using their internal threads.

What is a Threaded Hole?

Threaded holes in engineering refer to holes that have threads, distinct from tapped holes in their method of creation.

What are threaded holes used for in engineering?

In engineering, threaded holes play a crucial role in securing parts with mechanical fasteners. They are typically added using CNC machines and are often the final machining step after other elements of the part have been completed.

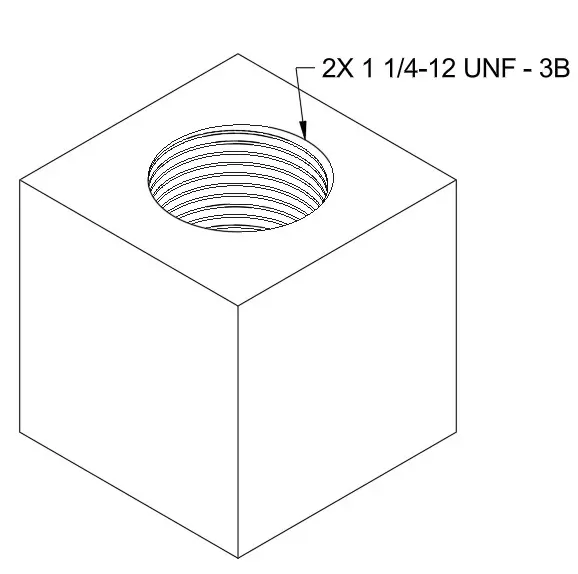

What is the callout symbol for threaded holes?

The callout symbol for threaded holes generally includes the diameter symbol 'Ø'. For metric threads, the diameter symbol is replaced with 'M'. The callout also specifies the threaded depth of the hole.

Get Your Free Quote Today

Don't wait any longer on your project!

Tapped Holes vs Threaded Holes

Tapped and threaded holes share similarities but are created through distinct machining processes. The key difference between threading and tapping lies in the tools used and the surfaces where these operations occur.

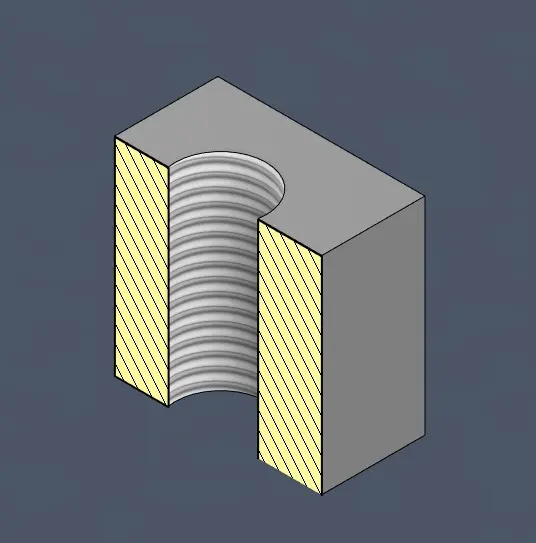

Tapped holes are drilled to accommodate machine screws, with threads cut directly into the inner surface through tapping. These threads securely hold threaded components like bolts and screws without requiring additional nuts.

Symbolically, a tapped hole is denoted on engineering drawings using specific callout symbols based on the thread standard. For metric threads, the diameter symbol is replaced with 'M', while Unified National Fine (UNF) specifies the thread type after the numerical dimension.

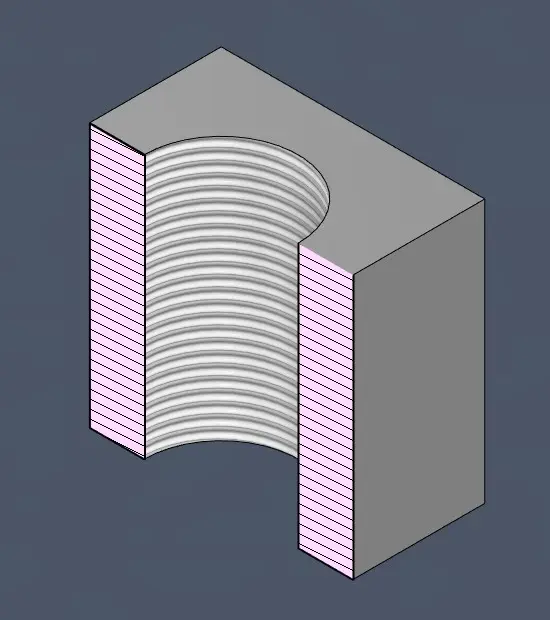

Threaded holes, on the other hand, have pre-existing threads and play a vital role in securing parts with mechanical fasteners. They are typically added in the final machining stages, often using CNC machines for accuracy.

Tapped

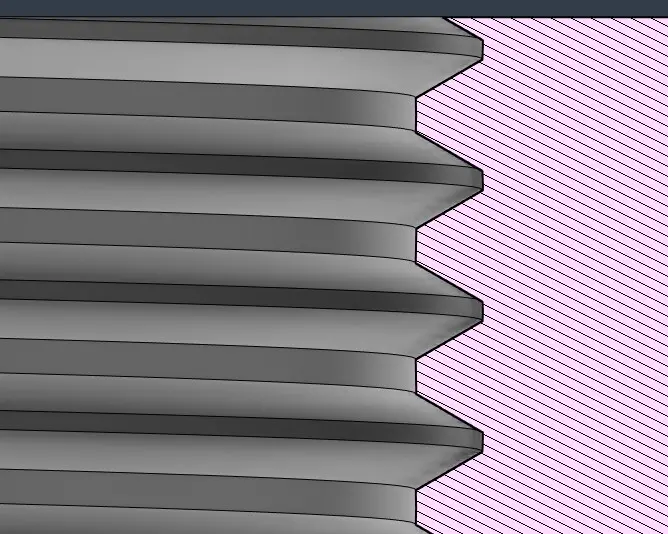

Threaded

Summary

Distinguishing between tapped holes and threaded holes is crucial in engineering and manufacturing for precision and functionality across applications. Tapped holes are drilled to house machine screws, with threads cut directly into the inner surface through tapping, ideal for securing bolts and screws without additional nuts. Their callout symbols vary based on thread standards, such as 'M' for metric threads or specifications like Unified National Fine (UNF).

Threaded holes, on the other hand, already feature threads and are critical for fastening parts with mechanical fasteners, often added in the final machining stages using CNC machines for accuracy. Understanding these distinctions and callout symbols is vital for optimizing manufacturing processes across industries, ensuring efficient part assembly and production.

Accurate Machine Products provides a wide range of manufacturing capabilities and value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.