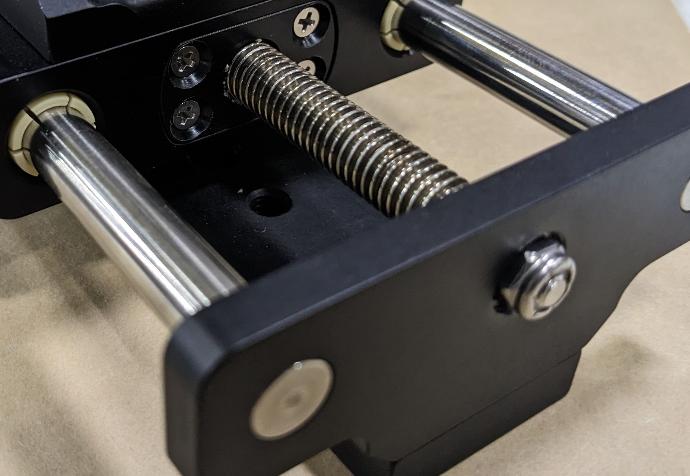

Precision Motion Control

A product that we assisted in developing and currently producing. Many components in the assembly require tight tolerances.

Other rotary devices and linear actuators have also been developed.

Fixture Designs

These components are part of a fixture that AMP designed and produced to facilitate the destructive testing of automotive assemblies.

Precision

Aluminum machined component with tolerances to less than 0.0005".

Also features a 'blind' keyway that required 'single point' broaching.

Heat Stakes

AMPCO heat stake tips. For plastic assembly.

Reverse engineered from customer supplied heavily used sample part.

Thread Gaging

NPT threads being gaged for proper depth of thread engagement.

Vibratory Finishing

Vibratory finishing is an abrasive process that we use on many of our aluminum parts that will be anodized.

The process results in a smooth consistent mate finish. Though polishing can also be achieved.

Anodizing

Anodizing is one of many surface finishing treatments we offer. When anodizing dimensionally critical components are great deal of care is required to assure proper fitment.

Painting

A simply product that requires; machining, laser cutting, forming, welding, riveting, painting, assembly and finish packaging.

All processes handled by AMP so the customer receives a self-ready product.